Are you a warehouse worker, exasperated at manually lifting heavy loads and transporting them from one place to another? Are you looking for an easier way to do your job so that you can focus on the more critical tasks at hand? Well, look no further!

Today, we will explore precisely what kinds of machines will alleviate these backbreaking labor issues and increase your efficiency. From automated guided vehicles (AGVs) to robust forklifts and robotic arms, a whole suite of warehouse assistance technology is available to improve anyone’s daily life in logistics operations. Let’s dive in!

What Kind Of Machines Save Warehouse Workers From Back-Breaking Work: Pallet Exchanger

Moving and exchanging pallets can be challenging and time-consuming, especially in industries that depend on quick and efficient operations. In this case, you might want to invest in machines from Top Industries — these machines are generally designed to automate the pallet exchange process, offering seamless and reliable performance. With a pallet exchanger, companies can say goodbye to inefficient manual handling and enjoy smoother operations with faster turnaround times. Many providers have garnered a solid reputation for delivering innovative and high-quality machinery that meets the unique demands of different businesses.

Contents

Automated Guided Vehicles (AGVs)

As technology advances, so do how businesses increase their efficiency and productivity. One such innovation that has taken the manufacturing industry by storm is using Automated Guided Vehicles, or AGVs for short. These vehicles are essentially self-driving machines capable of transporting materials and goods between different areas of a warehouse or factory.

Thanks to their ability to navigate and operate without human intervention, AGVs have revolutionized warehouses’ operations, allowing for greater accuracy and speed in delivering products to customers.

Autonomous Mobile Robots (AMRs)

The world of robotics has come a long way from the days of stationary, single-purpose machines. In recent years, the development of Autonomous Mobile Robots (AMRs) has changed the way we think about robots, giving them the ability to move about freely and accomplish various tasks independently. These robots use advanced sensors and software to navigate and interact with their environment, making them an incredibly versatile and powerful tool for industries like manufacturing, healthcare, and logistics.

Since they can work 24/7 without breaks, AMRs are a game-changer for businesses looking to increase efficiency and productivity. The possibilities of what these robots can accomplish are endless, and as technology continues to evolve, so too will their capabilities.

Automatic Packaging Machines for Faster Shipping

In the fast-paced world of eCommerce, every second counts. Automatic packaging machines have been the go-to solution in the shipping industry, enabling businesses to process orders at lightning-fast speeds. These machines are designed to pick, pack, seal, and label packages in seconds, greatly reducing processing time.

As they can handle a variety of package sizes and shapes, automatic packaging machines have become essential for businesses looking to stay at the forefront of the industry. They save time, reduce the risk of errors, and increase efficiency, allowing businesses to focus on what truly matters: delivering high-quality products to their customers as quickly as possible.

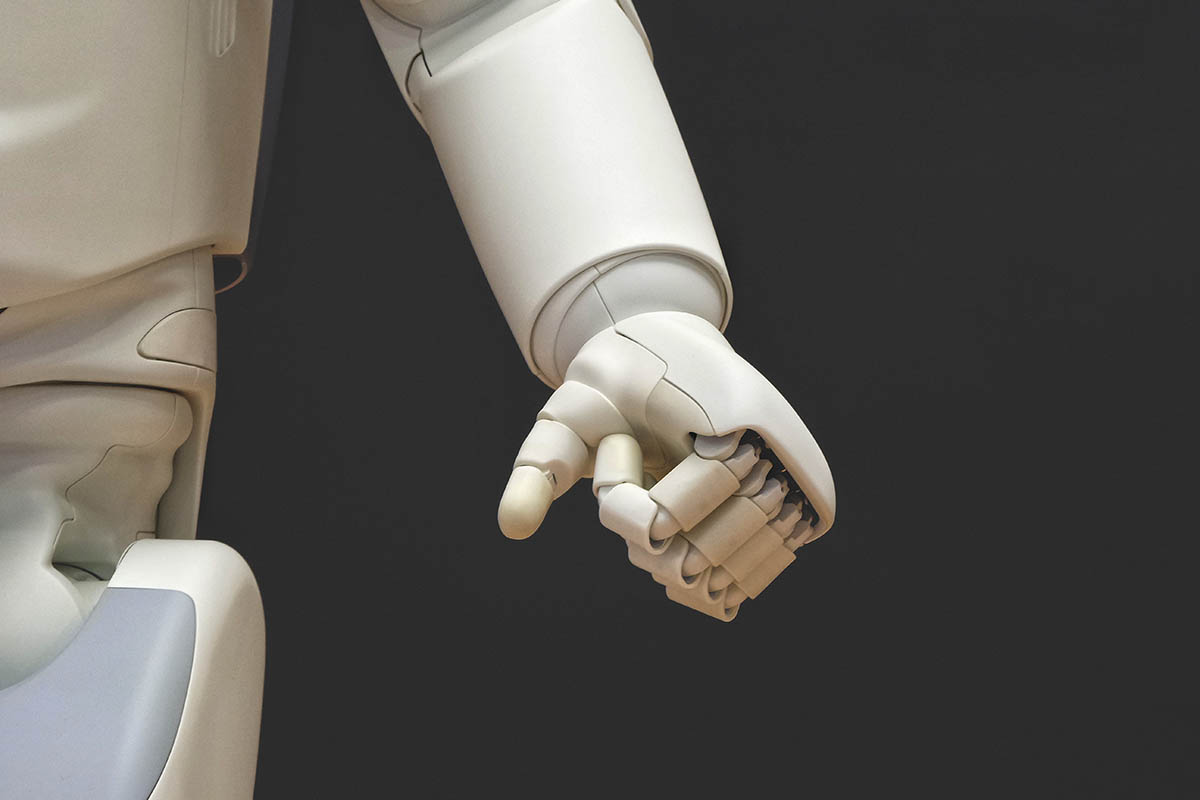

Robotic Arms

Robotic arms have long been a cornerstone of automation in various industries, and the warehousing sector is no exception. These advanced machines are designed to perform various tasks, from precisely picking up and placing items to sorting products and even operating complex machinery.

Through sensors and sophisticated programming, robotic arms can operate with an accuracy level that surpasses human capabilities, making them an invaluable asset in high-volume, precise tasks where errors can be costly. Their tireless, around-the-clock operation can significantly improve productivity, making them a smart investment for any warehouse seeking to optimize its operations.

Conveyor Belt Systems

A conveyor belt system is a classic yet highly effective warehousing tool. These systems are used to transport goods and materials around a warehouse or production facility with ease. By using conveyor belts, operations can run more smoothly and efficiently, reducing labor costs and improving turnaround times. Conveyor belt systems come in various shapes and sizes, from overhead to floor-level systems designed to meet the needs of any operation. They can be easily upgraded and customized to fit changing needs over time.

Benefits of Using Automation in Warehouses

Warehouses have come a long way from the manual labor-intensive spaces of the past. Automation technology has revolutionized how we handle inventory and streamline processes, significantly benefiting businesses. These include:

Lower Operational Costs

Automation in warehouses can significantly reduce operational costs. This reduction is achieved by minimizing manual labor, reducing errors, and increasing the speed of operations. Automated systems like AGVs, AMRs, and conveyor belts can perform tasks more quickly and accurately than humans, reducing the time and resources spent on corrections and reworks.

These systems can work around the clock without breaks or overtime pay, leading to substantial cost savings.

Improved Safety and Productivity

Automation in warehouses not only streamlines operations but also significantly enhances the safety of the work environment. Work-related injuries can be significantly reduced by relying on machines for potentially hazardous tasks such as lifting heavy loads or operating in high-risk areas.

In addition, automated systems are immune to the fatigue and distractions that can lead to human error, thereby increasing the overall accuracy and quality of work. The ability of these systems to function non-stop also means increased productivity, making it an ideal solution for businesses aiming for growth and efficiency.

Increased Storage Capacity

Thanks to automation, warehouses can dramatically increase storage capacity. Automated systems like AS/RS (Automated Storage and Retrieval Systems) can store items in high-density configurations, maximizing the use of vertical space and significantly reducing the footprint required for storage. This leads to more efficient use of space and the potential to house a larger inventory, ultimately increasing the scope of business operations.

Enhanced Customer Satisfaction

Automation in warehouses can also improve customer satisfaction. When you minimize errors and increase speed, automated processes ensure that orders are delivered quickly and accurately. This improved turnaround time can lead to a better overall customer experience, resulting in increased loyalty and repeat business.

Automation is the key to unlocking greater efficiency and productivity in the warehouse industry. Advanced technologies such as AGVs, AMRs, robotic arms, and conveyor belt systems can revolutionize operations with their ability to deliver greater accuracy, speed, storage capacity, and safety.

These automated solutions allow businesses to focus on what matters most: promptly delivering high-quality products and services. With the help of automation, warehouses can save time and money while improving customer satisfaction.